Czech Huisman upgrades welding robot to handle 15-ton weldments

Sviadnov, January 31, 2024 – Huisman Czech Republic has enhanced its welding robot at its development and manufacturing plant in Sviadnov. It now assists in the production of larger, heavier, and more complex steel components that were previously only weldable manually. With the installation of a multi-axis positioner, its capabilities in 3D printing have also expanded.

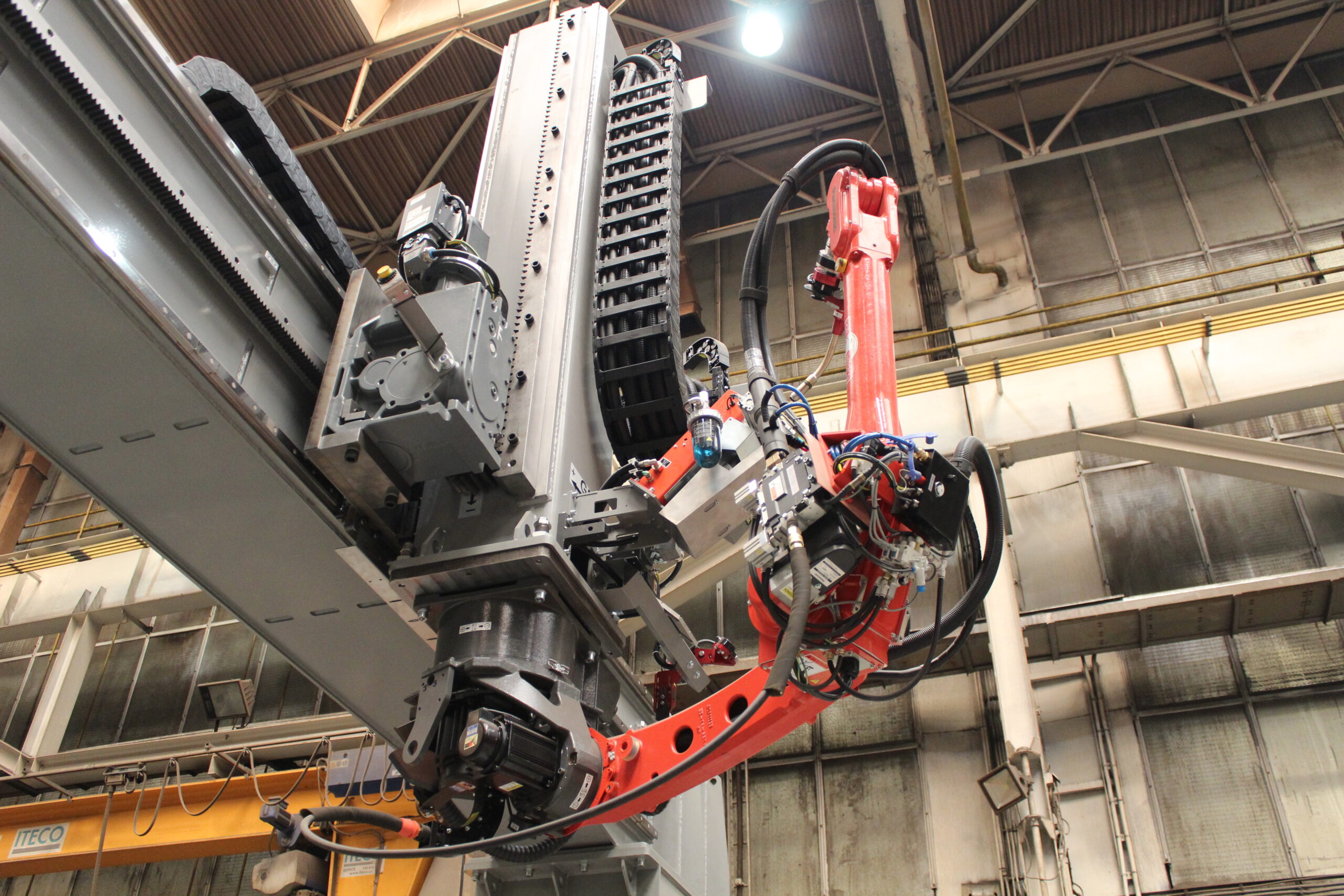

Alongside the robot upgrade, the robotic workstation itself underwent a transformation. “We extended it with a new travel track, a second column with a robotic arm, and also new positioners. With these improvements, we can execute weldments up to 24 meters in length and weighing up to 15 tons, overcoming the previous limitations of the robotic system. The new welding robot has become an essential part of our production, significantly impacting the efficiency and quality of our products,” stated Antonín Jedinák, Welding Leader at Huisman Czech Republic.

The expansion of the workstation also includes cutting-edge enhancements, such as the “ArcEye” 3D camera (real-time scanning for deviations), an automatic torch and brush changer for robotic weld cleaning, and a particular focus on the installation of a multi-axis positioner, bringing revolutionary possibilities in 3D printing using the WAAM (Wire Arc Additive Manufacturing) method. This innovation allows optimal positioning of printed components.

“In practice, we have successfully tested the multi-axis positioner in welding demo parts for our clients, achieving not only higher efficiency but also producing high-quality and precise products,” summarized Karel Pavlíček, Managing Director of Huisman Czech Republic. He added, “The robot excels, for instance, in the creation of components for crane trusses and other complex parts.”